Title Electrochromatic Glass Facades

A Case Study Application for Smart Window Technology

Author Patrick Bedarf

Year 2011

Type Article (Unpublished)

Intro

The use of transparent facades has become a leading feature in contemporary architectural design. Papaefthimiou (2010, p. 77) argues that, crucial reasons can be found in the demand for improving interior light conditions and visible connections to the environment as well as comfort and therefore inhabitation quality. Consequently, in order to establish a balance between user-defined demands and sustainable guidelines considering solar heat gain, cooling and heating requirements, complex sensor and interface-controlled, mechanically-driven facade systems such as louvers, blinds and dynamic lenses were applied in various buildings worldwide.

However, the durability and maintenance costs caused by these strategies are disputed. Manageability for users and reduction of system complexity are in demand by cutting down mechanically-driven solutions into material-embedded adaption. Therefore, the recent developments within the field of smart materials offer broad possibilities for deployment in large scale architectural glazing. The following article illustrates the insufficient glazing solutions in two case study buildings, the Kunsthal in Rotterdam and BK City in Delft and furthermore investigates which kind of smart material technology can be applied to the Kunsthal to improve the described situation at hand.

The comparative analysis

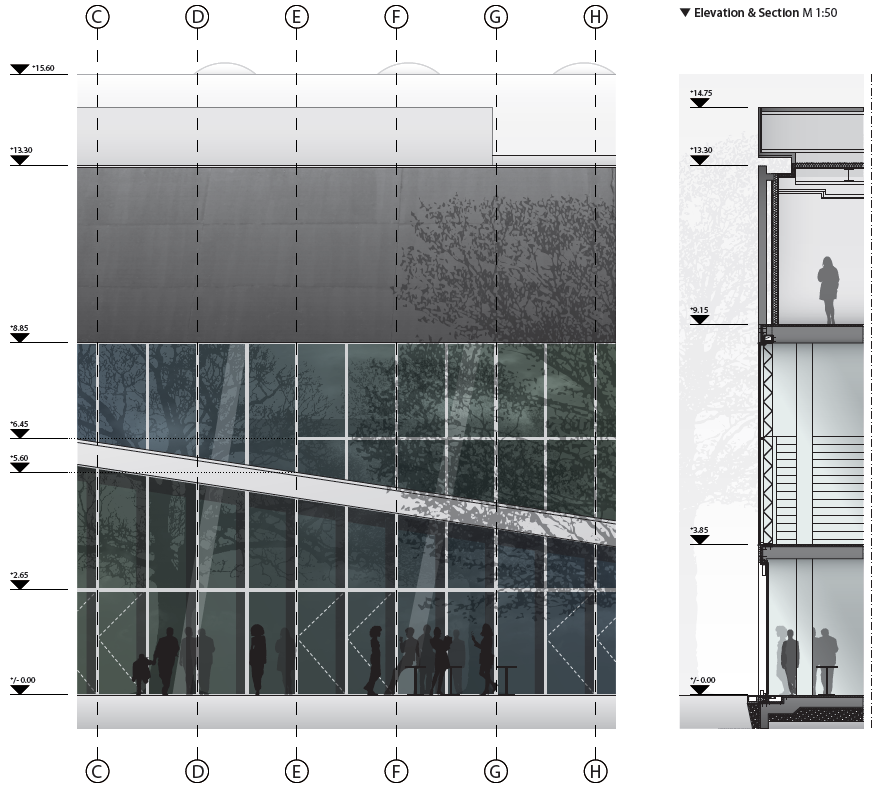

The Kunsthal by Rem Koolhaas appeals through the exceptional deployment of various materials such as extensive exposed concrete, corrugated PE-panels, travertine cladding, metal shed-roofing and fully glazed facade sections. Glazed facades are facing south-west and are executed as partly tinted double-glazing in a post-and-beam construction with only interior curtains for radiation protection. Consequently, solar radiation can enter the building through the glass skin and is only visually blocked or rather glare is avoided. The areas of consideration are the cafe and office spaces on the ground floor and the auditorium space above. Since these places are in need of user-operated daylight management, the existing applications of curtains which are consisting of black coloured fabric seem to be plausible. However, the insufficient prevention of solar gains results in overheating during sunny periods at midsummer.

The BK City as a complex consisting of an existing building and two extension halls, shows as well several insufficiencies regarding glazing. First, the existing masonry building contains existing single-glazed windows in slender steel frames which are highly responsible for energy loss. Secondly, the extensive glazed facade of the extension halls, deploy only interior curtains for radiation protection. The applied system consists of a metal post-and-beam construction carrying the clear double-glazed window elements of a standard grid size of 1.25 x 1.25m. Inside, large black-coloured cloth curtains are used to prevent glare resulting from direct sun radiation. Consequently, solar radiation is stopped by the curtains after it passes the glazed facade layer and enteres the building interior causing heat gain in the workspaces of students at the Zuid Zerre and The Why Factory facilities.

Comparatively, both applied solutions offer the possibility to adjust the amount of visual daylight which enters the building accordingly to the environmental conditions and the indoor work setting. However, in both examples sun radiation flux is transmitted through the facade layer and causes negative indoor climate results of overheating. Increased efforts for cooling are the outcome which puts excess strain on the ventilation system and raises the overall energy consumption drastically. Furthermore, the implementations of black-coloured curtains sacrifice a major part of the visibility spectrum to the surrounding environment.

Smart solutions

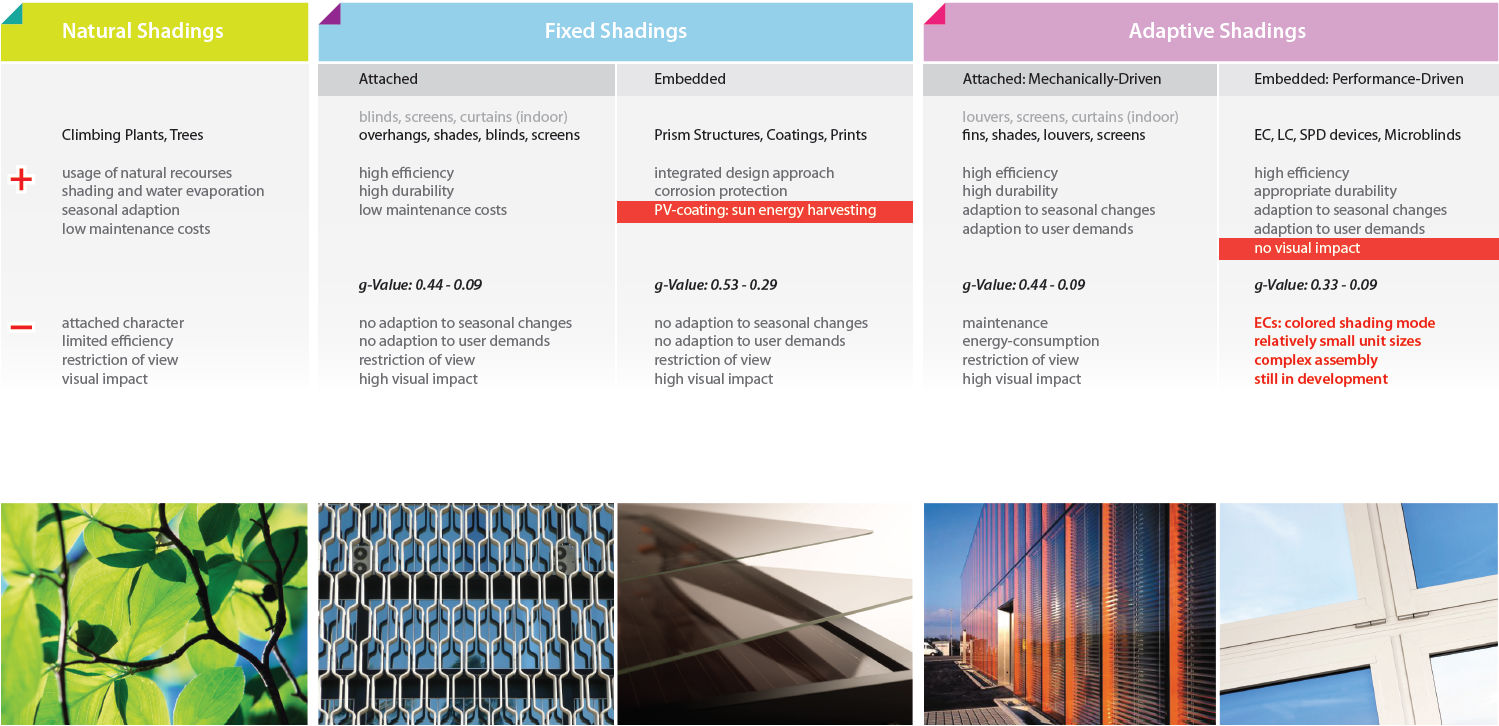

As described in the introduction smart materials offer vast possibilities to improve the described energetic performance of large-scale glazing. Smart windows typically have to feature control of optical and thermal transmittance and view. In this respect, Papaefthimiou (2010, p. 79ff) states that chromogenic materials have been developed and tested in different industries waiting for their application in building technologies. Chromogenics describes a class of materials which are able to change their optical properties by an alteration in an external energy source. They cover any visibly switchable technology useful for glazing, mirrors, transparent displays and various other applications. Describing the chromogenic family, Ritter (2007, p. 74) distinguishes between (1) Photochromics – PCs, which change their color when exposed to light, (2) Thermochromics – TCs, which change their color due to temperature changes, (3) Chemochromics – CCs, which change their color when exposed to specific chemical conditions and (4) Electrochromics – ECs, which are able to change their color when a certain voltage is applied. ECs also include related technologies such as liquid crystal (LCs) and suspended particle devices (SPDs), which feature similar effects when electrically activated.

Although, the alluring ability to change the optical properties of materials belonging to the family of PCs, TCs and CCs appears promising, the direct transfer into architectural application is marked by insuperable difficulties. First, the chemical substances used in that technology are unstable and have short life-spans. Additionally, the applications of substances such as PCs have so far been limited to small-sized products like sunglasses or helmet visors. Operating on the scale of entire buildings would expose these materials to considerable fluctuations in external conditions and intensive abrasion. Aside from that, materials such as TCs strongly scatter reflected and transmitted light when switched to dim-mode and sacrifice a high amount of view. Unfortunately, TCs are limited in efficiency for solar radiation protection and can therefore only reduce glare due to direct sunlight.

EC (Electrochromic) Materials

Electrochromism was the first technology heavily invested in by glazing and façade manufacturers during the 1970s and 80s. An EC window is an active solar control device whose transmittance in the visible and near-infrared part of the spectrum can be reversibly manipulated by the application of a low voltage (typically 1-5V DC). A typical EC device resembles a thin-film battery attached to a five-layer assembly of (1) a transparent and electrically conductive film mounted on glass or plastic, (2) an EC film, (3) an ion-conducting electrolyte layer, (4) an ion storage layer and (5) a second transparent conductive film. EC glazing has become one of the most used chromogenic technologies for building facades, due to their ability to maintain spectral transmission during changing transparency levels. Therefore they are used in various scenarios including exterior glazing, skylights, glasses and visor applications.

LC devices (liquid crystals)

Liquid crystal technology was been applied for some time in wristwatches and is nowadays the primary chromatic technology used in large panel displays. Therefore, there has already been significant effort to test and refine the technology for their deployment on large scale exterior surfaces. Since LC technology came into the architectural market ready-to-use, it is gaining popularity as privacy glazing. Technically a thin layer of liquid crystals is sandwiched between two transparent electrical conductors on thin plastic films, and the entire device is laminated between two layers of glass. When power is off, the liquid crystals are in a random and unaligned state. They scatter light, which makes the glass become translucent, thus obscuring direct views and providing privacy. When power is applied the crystals align linearly and allow light passing through the system.

However, in reducing unwanted infrared radiation (and interior heat gain) the LC devices are hardly satisfactory because only their specularity can be modified, not the transmitted energy. In addition, the linear alignment of the crystals in transparent mode, considerably reduces view from oblique angles. Another remarkable disadvantage is the continuous need for power supply of LC devices in order to stay transparent.

SPD devices (suspended particles)

SPDs are an alternative to LCs for privacy applications and are made of an electrically controlled film with a thin, liquid-like layer in which molecular needle-shaped dipole particles are suspended in a polymer matrix between sheets of glass with embedded transparent conductors. When electricity comes into contact with the SPDs, which have a transparent conductive coating, they line up in a straight line and allow light to flow through. Once the electricity is turned off, they move back into a random pattern and block light. However, since the device requires continuous power to be clear, the power consumption is higher than for ECs.

In summary, SPDs are showing the same insufficiencies as LC devices, regarding the reduction of infrared transmission and energy consumption for maintaining the transparent stage. In addition, they have even less ability for their spectral profile to be modified towards one color or another. Because of their primary advantage over LCs to permit much more oblique viewing angles, they have already been installed in various applications such as facades, conference room windows and partitions, automotive and aircraft glazing.

Architectural Application

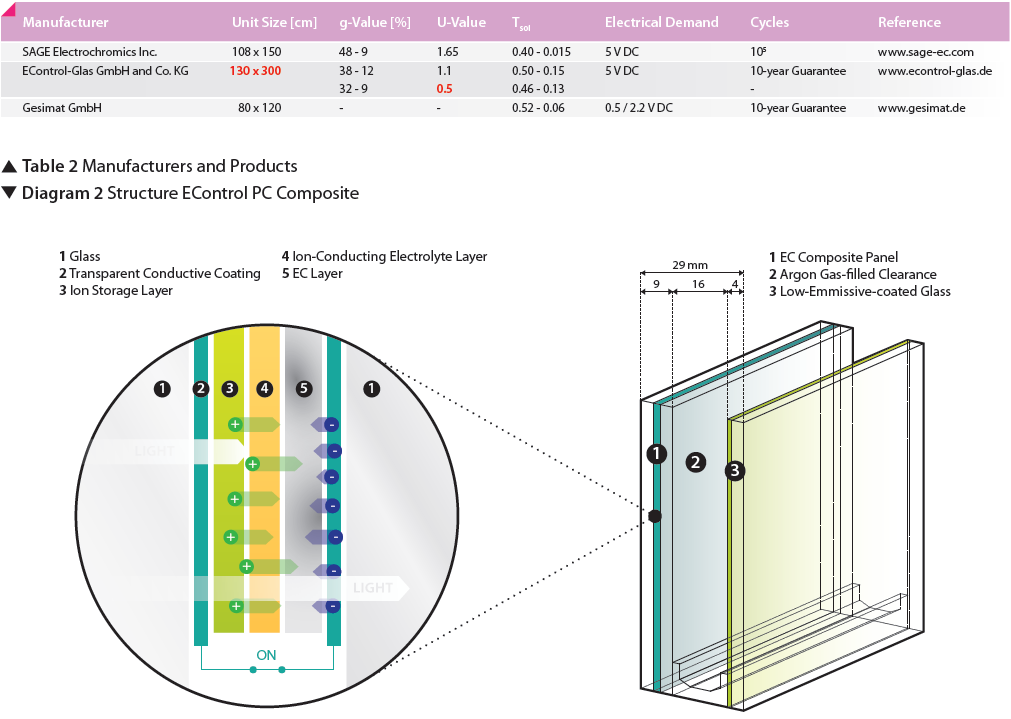

In evaluating an applicable product solutions for the Kunsthal, one needs to mention that many glass and coating manufacturers have developed smart glass technologies in the last decades. Baetens (2010, p. 95) emphasizes that ‘it is important to know how current commercially available smart windows perform, which properties they exhibit and how reliable the products are’. Furthermore, Baetens introduces the main three manufacturers which are able to produce functional windows employing EC technology: SAGE Electrochromics, EControl-Glas GmbH and Gesimat GmbH. In comparing their product’s performance regarding the transmittance in the visible and complete solar spectrum, it turns out that all manufacturers can produce windows meeting the desired demands for architectural glazing. Extensive testing on durability unveiled life-cycles of up to 105 switching procedures which resemble 30 years, within the temperature range of -30 to 600C. Based on their low U-values of 1.1 and 0.5 W/m2 by implementing an argon-filled cavity or triple glazing and the achievement of acceptable unit sizes of up to 1.30 x 3.00m (starting February 2011, EControl System Description 2010, p. 2), the products of EControl-Glas meet the requirements for applying them to the case study in question. In summary, Beatens (2010, p. 97) concludes that ‘the possibility to produce large-area electrochromic windows according to the standards for exterior building glazing with a good durability’ is proven.

By way of example, in 2009 Hahn-Helten Associated Architects used the described system of EControl-Glas for their Science College Overbach project in Germany. Hereby, they met the requirements of passive energy standard in using innovative building technology details such as switchable glazing. Furthermore, the system is applied at the glazed skywalk of the Fraunhofer Institut IST in Braunschweig, Germany. An example addressing the domain of building preservation and renovation is the Elsterschloss Gymnasium, a school located in a historic castle setting in Elsterwerda, Germany. Consequently, the EC-windows were placed at the side wing of the building ensemble to improve the energy performance while preserving an original appearance. Finally, there are several examples of applications at single family houses.

Technically, the system of EControl-Glas is assembled of (1) an exterior 9 mm EC-composite glass panel, followed by (2) a 16 mm wide argon-filled cavity and sealed off by (3) an interior 4 mm low-e coated float-glass panel. Additionally, a triple-glazed setup can be achieved by embedding a security glass panel. In case of the Kunsthal no necessary improvements are needed regarding the U-value of the facades facing south-west. Therefore, the loads of the double-glazed system can be estimated with 32 kg/m2 which are comparable to the existing windows. Consequently, the existing post-beam construction proves to be an adequate structural solution. To supply the individual glass panels with electricity, the connector positioned centrally at the top edge of the composite window panel needs to be connected to the wiring circuit which can be embedded into the structural façade elements preferably posts. Furthermore, each window can be controlled via frame-gated light sensors or the main control unit running on 24V DC. Additionally, a connection to the building services management system can be established.

Potential of Electrochromics

To effectively draw conclusions about the applications of EC-windows, it is necessary to ponder future market demands, politics on energy efficiency and possible technical improvements. Firstly, it is assumed that the demand for large-scale architectural glazing won’t decrease in the upcoming decades and the need for quality-of-life enabling technologies particularly in the private housing sector will continue to grow. Secondly, these tendencies will be largely accompanied by necessary movements towards energy efficiency of buildings and facades. Referring to this, EC windows have proven to be reliable switchable devices which can optimize the energy performance of buildings through the reduction of heating, cooling and lighting loads.

Additionally, Papaefthimiou (2010, p. 111) summarizes that, ‘Clear glass gives comparatively small need for artificial lighting but is disadvantageous with regard to cooling energy, while tinted or reflecting glass diminishes the cooling energy but increases the demand for lighting’. Furthermore, he places emphasis on realizing one of the main features of smart windows when evaluating their efficiency: a high performance level while providing an unobstructed visual contact between indoors and outdoors. Therefore, conclusions can be drawn from enhanced indoor comfort and the resulting effects on well-being and working efficiency. As a matter of fact, the feature of invisible improvement of building energy performance makes EC technology particularly attractive for building preservation.

Finally, technical improvements of other industries such as automotive and aircraft design are expanding possible applications of EC devices continuously. Baetens (2010, p. 97) points to combinations of smart material composites and photovoltaic coatings, such as the latest developments of Peer+ in Eindhoven, The Netherlands. However, EC glazing is still in development and even though notable manufacturers are able to produce high performance EC devices, there is still a long way to go. Since EC-glazing has proven its vast potential, further development needs to be done in research for architectural applications.

References

Behling S, S 1999, Glass: Structure and Technology in Architecture, Munich

Papaefthimiou S 2010, Advances in Building Energy Research: Volume 4, London

Grondzik WT, Kwok AG, Stein B, Teynolds JS 2010, Mechanical and Electrical Equipment for Buildings, New Jersey

Bradshaw V 2006, The Building Environment: Active and Passive Control Systems, New Jersey

Binggeli C 2010, ASID – Building Systems for Interior Designers: Second Edition, New Jersey

Klooster T 2009, Smart Surfaces: And their application in Architecture and Design, Basel

Addington M, Schodek D 2005, Smart Materials and New Technologies: for Architecture and Design Professions, Harvard

Baetens R, Jelle BP, Gustavson A 2010, Solar Energy Materials & Solar Cells, Trondheim

Ritter A 2007, Smart Materials in Architecture, Interior Architecture and Design, Berlin

Zhao Y, Ikeda T 2009, Smart Light-Responsive Materials, New Jersey

Margolis L, Robinson A 2007, Living Systems: Innovative Materials and Technologies for Landscape Architecture, Basel

Detail Magazine 1/2010, Issue: Green

Detail Magazine 4/2004, Issue: Building with Light

Heinzelmann F, Teuffel P 2010, Adaptive Daylighting Structures. Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium Shanghai, Shanghai

GlassX. http://glassx.ch, last page visit 24.11.2010

Peer+ Smart Energy Glass. http://www.peerplus.nl, last page visit 30.11.2010

EControl-Glas. http://econtrol-glas.de/, last page visit 03.12.2010

http://www.chromogenics.com/, last page visit 03.12.2010