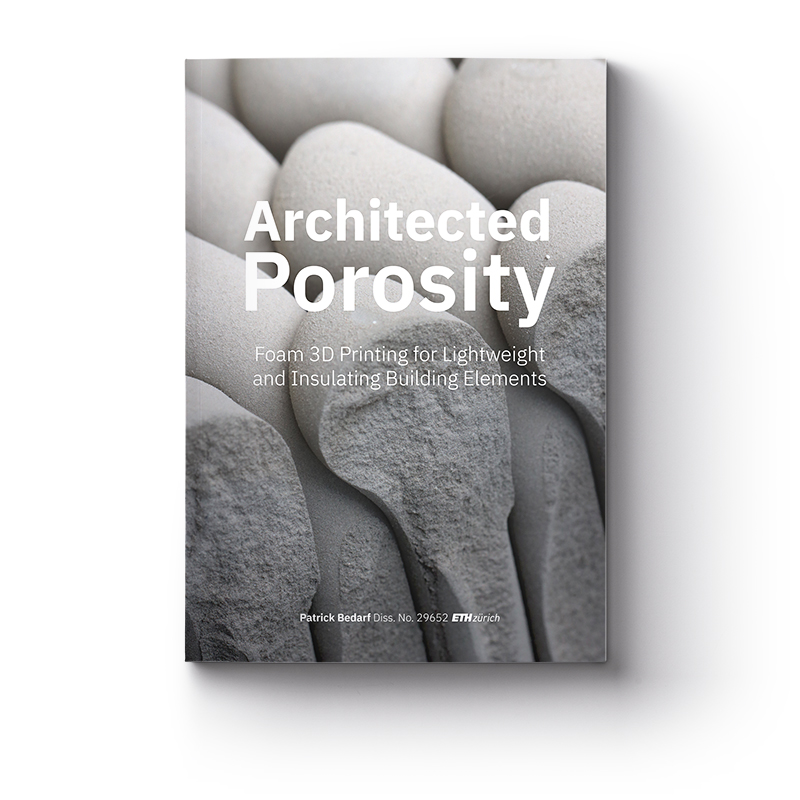

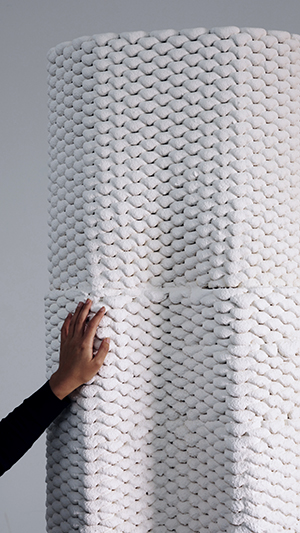

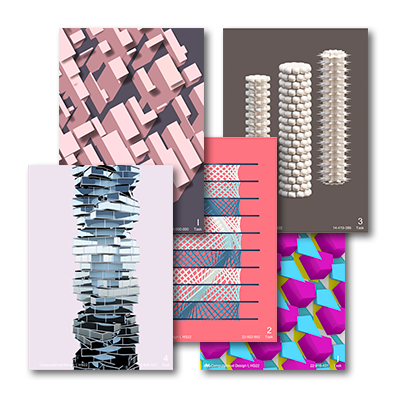

Foam 3D Printing for Lightweight and Insulating Building Elements

Author Patrick Bedarf

Published in Cummulative doctoral thesis, ETH Diss. No. 29652

Year 2023

DOI 10.3929/ethz-b-000643980

Abstract Porous materials are ubiquitous. They make the bones of birds lightweight for flight and one of the oldest staple foods of humankind, bread, easy to digest. Distributing nothing inside something unleashes transformative powers and fascinates designers and engineers alike. In construction, different porosities are conventionally combined by pressing, bolting, or gluing materials together to make building parts lighter, thermally insulating, and endow them with additional properties. In contrast, this thesis asks what architectures would become possible when building with varying porosities in one holistic materialization process: large-scale 3D printing of foams. The most pressing environmental challenges of the construction industry are addressed by proposing a design and manufacturing framework. This framework enables the creation of lightweight and insulating structures that require less material, resulting in a lower carbon footprint and reduced operational energy requirements for heating buildings. The cumulative thesis is comprised of four main publications: an opening review defining the research field, followed by three consecutive milestones advancing the main research objectives on a small, medium, and large scale. A robotic 3D printing setup is prototyped, subsequently scaled, and refined in alignment with the material development. Computational design strategies are explored and developed for building part geometries and print path infill schemes. These methods are tested in three real-scale prototypes for architectural applications. By combining digital fabrication technologies and state-of-the-art material science, this interdisciplinary research explores the unknown design potential of foams for innovative building components and envisions a more environmentally friendly and sustainable construction culture.